A supply chain is only as strong as its weakest link. For far too many businesses across multiple industries, the warehouse is that weak point. There’s a tendency for many owners to see their storerooms as static — nothing more than glorified storage lockers. However, those who understand the importance of a warehouse know how dynamic and vital it is for the overall efficacy of their operations. There are a lot of moving parts inside these facilities, and they all need to be kept in good working order to ensure the best results.

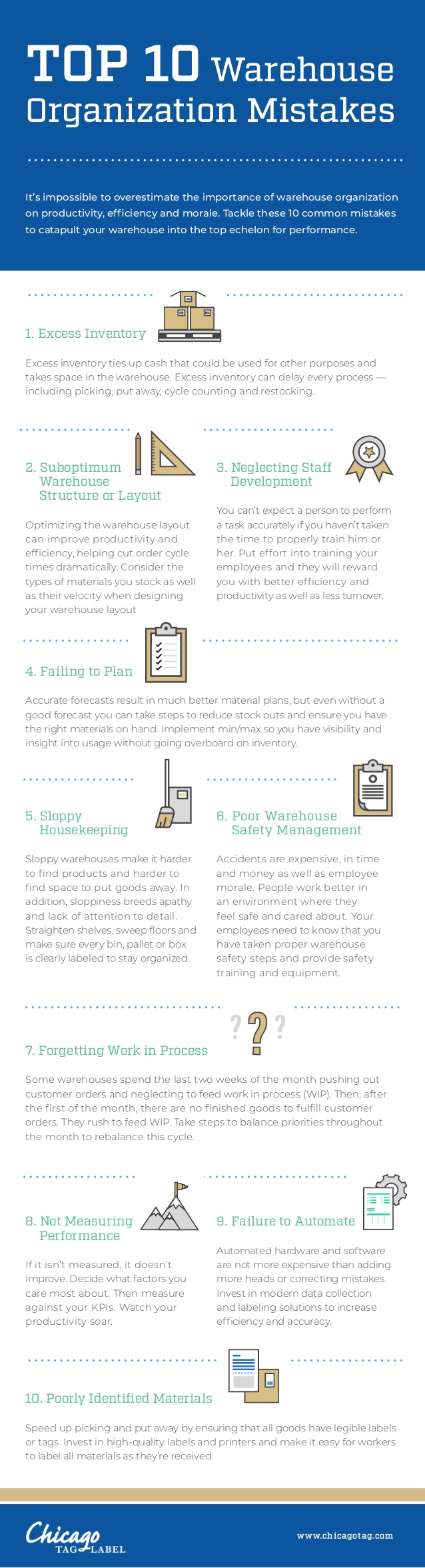

Unfortunately, many companies fall into organizational mistakes that harm the productivity, efficiency and morale within their warehouses. Correcting these errors is critical for achieving a safe and effectual facility, and every manager should be on the lookout for them.

For instance, one of the most common missteps many enterprises make is tying up too much of their cash and space with excess inventory. This can create a domino effect, impacting other processes including picking, cycle counting and restocking. Maintaining a proper level of products and supplies means less confusion and clutter gumming up the works.

Of course, overstocking is often a symptom of failing to have a solid plan in place. Getting accurate forecasts is vital for predicting demand and ensuring a healthy reserve. The more insight you have into your usage and procedures, the easier it will be to keep the right amount of goods on hand.

No matter how much forecasting you do, however, it can all be for naught if there isn’t a basic system of organization. Sloppy housekeeping can lead to mistakes, damaged goods and slower output. This is why it is necessary to keep up with straightening shelves, proper labeling and even sweeping the floors on a regular basis. A clean warehouse is a prosperous one.

It’s also crucial to have up-to-date safety management to swiftly and effectively handle any incidents that occur. Creating a safe workplace means your staff will put in their best effort because they will know they are valued and protected.

Don’t fall into the trap of assuming your stockroom doesn’t need your attention. By watching out for these and other common organizational mistakes, you can improve the performance and overall success of your supply chain. The accompanying infographic contains these and many more tips you can use to make real improvements in your warehouse.

Don Amato is Vice President of Sales for Chicago Tag & Label, which manufactures form labels, labels and tags that deliver solutions to a broad range of industries including retail, industrial, manufacturing, distribution and medical environments.

Leave a Reply